Back

Studio

Lote Art School

June, 2012

x

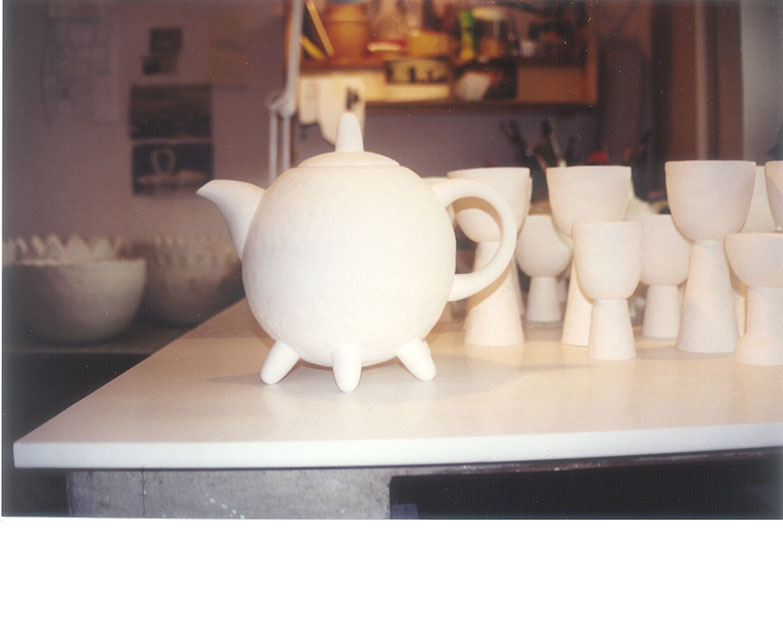

Studio Photographs

2012 - 2016

x

Making Teapots

2004

1. Mixing liquid porcelain mass with water. It should become perfectly smooth.

2. Pouring the mass into gypsum mould. Gypsum extracts water from liquid porcelain and facilitates drying. After some minutes I can pour extra liquid out of the mould. Something like a crust stays in the mould. Approximately day later a solid piece can be taken out of the mould.

3. Various pieces to assemble (a separate mould for each piece). Liquid porcelain (on the right side, arrow) is used to glue (attach) these pieces together.

4. Process of assembling. Small holes are made in closed parts (e.g. legs), otherwise these hermetic enclosures would blow up during the firing.

5. Teapot ready for first (“biscuit” at 900 C) firing. Still it needs some days to dry out completely. Presence of water would destroy the teapot when the temperature rises (no steam!).

The teapot is now approximately by 10% larger than the finished one. It will stay the same size after the first firing (it will shrink by 10% during the second firing).

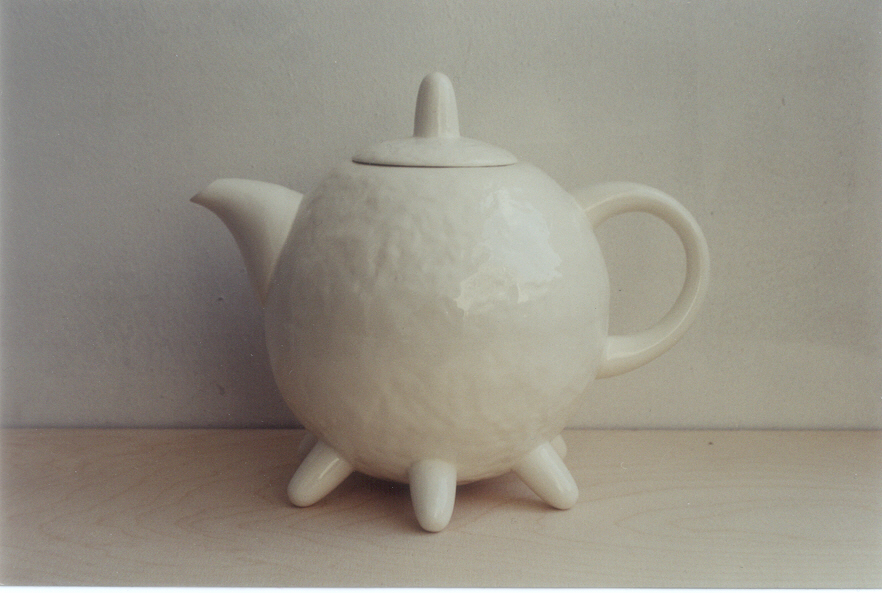

6. Teapot after the first firing (at 900 C). The color has changed to light pink, and the teapot now is light and very fragile. The form and size has not yet changed.

7. Glazing. I put the teapot in glaze liquid. That should cover the surface evenly, no drops or streams are allowed. After the glazing the teapot should dry completely, that takes couple of days.

8. After the high temperature (1240 C) firing. The teapot has reduced (by approx. 10%) in size.

Now it is ready for surface decoration - painting.

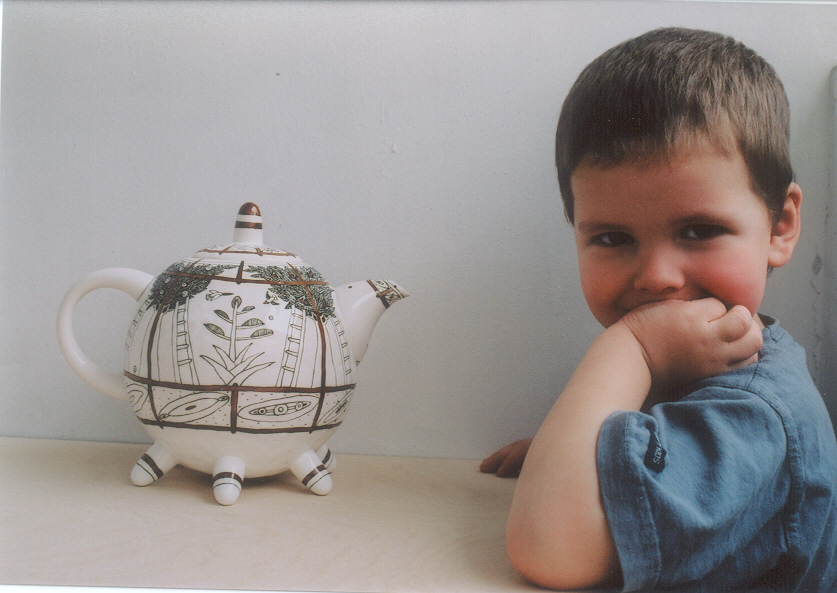

9. Initial graphic black&white drawing started (black pigment, mixed with sugar and water, so it doesn’t dissolve in turpentine based colors)

10. Graphic drawing continued.

11. Graphic drawing completed; gold parts covered (doesn’t look like gold, yet!).

12. Graphic drawing observed by our son Janis Martins – he likes the process!

13. Color painting started – these colors will change slightly too, after the firing.

14. Your teapot after “low temperature” firing (750 C); it will require another firing (by 10 degrees less, 740 C, not to spoil the first color firing) for small corrections! (apologies for film defect on the left).

x

Website by Milda Ošiņa